16 Jun 2023

doorOneThird

We often hear about subjective and objective quality control for fresh produce, but the difference can be confusing.

This post will explain the differences between subjective and objective measurements and how they are used for QC.

What is a Subjective Measurement?

Subjective means the measurement you are performing can be influenced by a person’s opinion.

Think of it like this: subjective results are subject to interpretation.

Subjective Quality Assessment Examples

An example of a subjective measurement is visual defect inspection by employees. If employees look at individual fruits and vegetables to analyze defects then it is subject to their bias.

The very best of operations have minimal variation between inspectors, and this can require years of training.

Problems With Subjective Measurements

Because subjective measurements rely on human interpretation, measurements can vary for different employees.

For example, one employee may pass a banana that the other wouldn’t have in a quality check.

Fresh produce companies use many subjective measurements because they seem simple. Freshness experts must be trained to have repeatable and reproducible results.

However, this is expensive and still not as accurate as an objective measurement would be.

What is an Objective Measurement?

Objective means something is driven by data and facts, without personal bias.

An objective measurement is something that you can base decisions on that is not influenced by human opinion.

By having objective measurements in place, there is no guesswork or room for human error. All measurements have the same basis.

Examples of Objective Quality Control Measurements for Fresh Produce

There are a few useful objective measurements for fresh produce.

Some examples are temperature profiles, Brix, and objective shelf life predictions.

These measurements are only objective when they are not subject to a human’s interpretation. For example, an employee manually squeezing peaches to test firmness is not objective. Using a tool to apply the same force to every peach and noting that force recording is objective.

Wageningen University has an interesting video that summarizes objective quality control in the fresh chain.

What Does it Take to Be an Objective Standard?

We know that objective quality control is helpful, but can you take any measurement (firmness, for example) and base all your decisions on it? No.

An objective standard is an accurate and reliable indicator of what you want to control.

For example, if you want to control freshness, then shelf life could be your objective standard. However, shelf life determined from leaving products on a shelf until they rot is subjective. It also doesn’t account for variation between batches.

Instant shelf life prediction measurements based on intrinsic product quality are a reliable objective standard.

Why Objective Shelf Life Prediction is So Effective

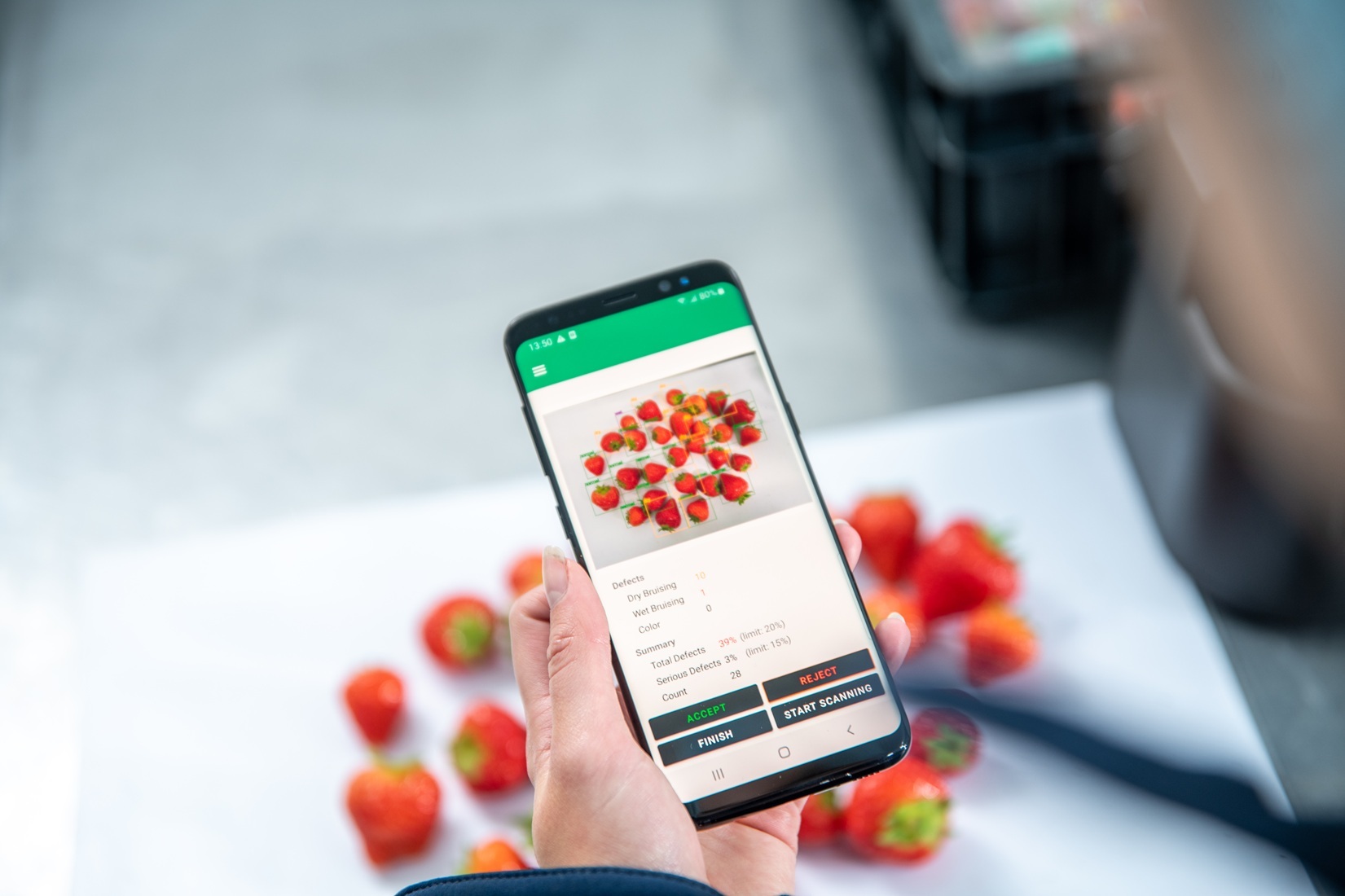

There is no variation in shelf life predictions between employees when measured objectively. In this case, a handheld scanner and algorithms are what determines the shelf life in this case- not the employee.

This also means that you can hire someone new and have them at an equal level of measuring shelf life as an expert who has been there for 12 years.

Of course, if you still have other subjective measurements to perform, this new hire will be behind the curve. This is why it is beneficial to implement objective measurements wherever is reasonable in your business.

Be sure to read our free Ultimate Guide to Fresh Produce Shelf Life Prediction to learn more.

How To Begin Predicting Shelf Life of Fresh Produce

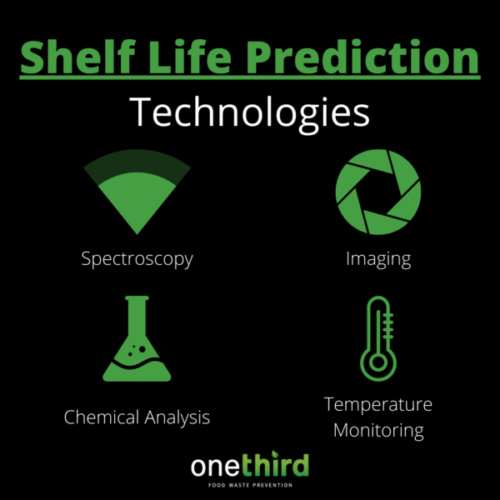

To perform objective quality control for fresh produce you must use the necessary tools. There are four main methods of predicting shelf life in fresh produce.

The best method depends on the specific application. Are you wanting to quickly assess a batch of strawberries and see how it compares to others? Then OneThird’s spectroscopy solutions are probably best for you.

There’s no single solution that will fit every application and prevent all your food loss. This is a complex issue that is best fought with a variety of tools.

OneThird makes shelf life prediction solutions for growers, distributors/wholesalers, and retailers.