.jpg)

6 Jan 2026

doorOneThird

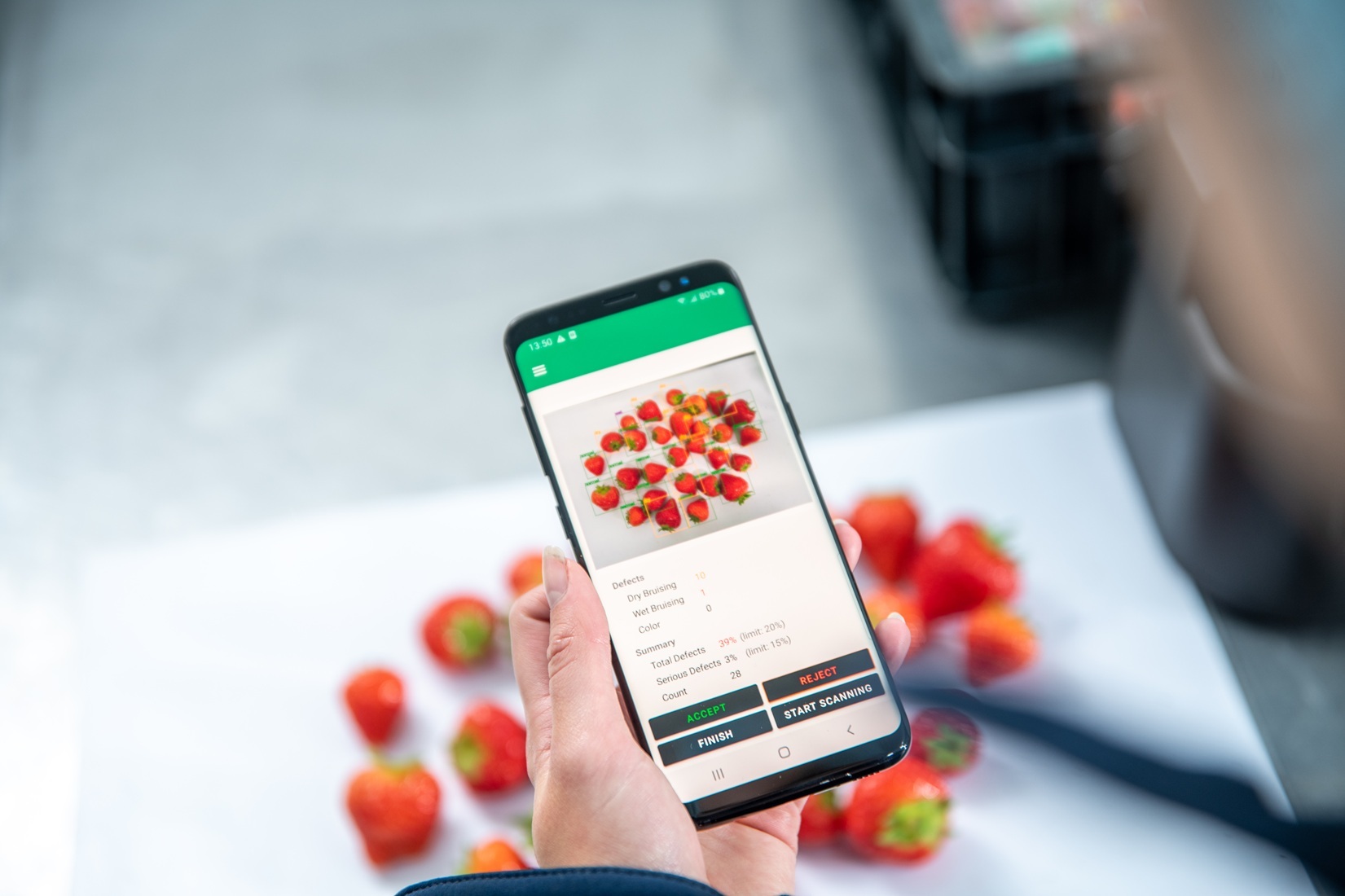

OneThird, a data-driven fresh produce tech innovator, proudly announces AI-driven Visual Inspection. This innovation brings exceptional speed, objectivity, and efficiency to soft fruit quality control. Fully integrated into OneThird's Digital Quality Platform, the new tool complements the company's existing tools for non-destructive and objective assessment of brix, firmness, and dry matter. Creating holistic end-to-end insights of quality in the fresh produce supply chain; from farm to stores.

Through highly automated AI-based visual inspection, OneThird enables users to rapidly and objectively evaluate key quality parameters, including size uniformity, visual defects, and color intensity. Within seconds, the system identifies deviations such as bruising, mold, white shoulders, misshapen berries, and discoloration. Users can zoom in on each berry for detailed inspection, enabling precise, consistent, and fully digitalized quality grading. As the data is collected in OneThird’s cloud platform, reports are immediately available and can be compared with other lots, enabling efficient and data-driven decision-making.

“With our AI-based Visual Inspection Tool, our customers can screen incoming batches up to ten times faster than through manual inspection. By digitizing and automating this process, they gain substantial time savings. This allows for faster decision-making and creates more transparency between growers, distributors, and retailers. Resulting in a more efficient supply chain,” says Marco Snikkers, Founder and Head of Product at OneThird.

Digitization, automation, and real-time insights

Digitization and automation have compelling benefits. Meaning fast, objective, precise grading ensures actionable insights that reduce labor burden and save food waste. The technology and software are easy to implement and applicable throughout the fresh produce supply chain. OneThird's digital platform allows for trend analysis, supplier performance comparison, integrated Quality Management System workflows, and more.

Getting the right product to the right customer, at the right time, can save customers up to 25% reduction in food waste by optimizing best-before dates, shipping routes, and repurposing surplus produce. OneThird drastically reduces the manual labor required and delivers immediate savings of up to 50% in QC labor costs by streamlining how QC data is acquired and cataloged.

A holistic approach to better understand quality

OneThird has a strong focus and an extensive database on the quality of strawberries, blueberries, and avocados. Next to replacing destructive, manual and slow tests for Brix, dry matter, and visual defects, combining all these parameters leads to a more holistic approach to quality. Leading to key insights for shelf-life prediction and taste assessments. Helping breeders, growers, and retailers to improve the overall quality of produce.

OneThird will showcase its AI-driven Visual Inspection and the OneThird digital QC platform at Fruit Logistica in Berlin from February 4-6, 2026. Visit OneThird to demo the technology in Hall 3.1 at booth D-25.