16 Jun 2023

doorOneThird

If you work in a facility that handles perishable goods of any kind, there’s a strong chance you hear the terms “FEFO” and “FIFO” thrown around.

In our experience, there are misconceptions about FIFO versus FEFO.

This blog post is meant to provide clarity on the differences and discuss what you need for a true FEFO operation.

What is FEFO?

FEFO stands for “first expired, first out.” It’s a method of shipping that just means you send the products expiring soonest first, even if they weren’t the first ones to enter your facility.

The other common method used in warehouses is FIFO, or “first in, first out.”

Many companies claim that they are shipping in a FEFO method- but are you really?

Do You Actually Use FEFO?

It’s easy to say that you ship FEFO. But how are you proving that you are indeed sending the first batch to expire out first?

You need an objective standard that can be used to assess different batches without bias. Subjective, visual assessments done by multiple employees are simply too biased.

Based on the huge amount of food loss and waste in the world, it’s likely that very few companies successfully maintain a true FEFO operation.

Shelf life can vary widely for a variety of fresh produce. One batch can last three days and the next can last 16 days, depending on a multitude of variables.

When subjective measurement standards are used to assess expiration dates, the dates cannot be trusted.

Likely, you sit somewhere between FIFO and FEFO until you have an objective shelf life standard.

The Current State of Food Loss and Waste

Around 40 percent of food wastage occurs in the supply chain in developed areas of the world. This can be due to pests, poor cold chain management, physical damage, and a variety of other reasons.

However, much of it is caused by poor freshness management. Are you using shelf life as a metric when deciding what to ship next? Or are you simply using visual assessment and what your staff believes should be shipped first?

Most companies just accept a certain level of loss and waste with their products. However, this is expensive and harmful to the environment. All while over 10% of the world is going hungry.

It’s a major initiative for the food system to halve food loss and waste by 2030 for many reasons. This means we must take steps now to reach our goals laid out by the UN.

How to Truly Switch to FEFO

It’s too common to have a subjective metric for assessing the expiration date. The problem with this is you run into human error and it requires a lot of labor.

The key to implementing FEFO in your business is comparing different batches objectively.

Is your metric the percentage of marketable products? Is it the average shelf life of a batch?

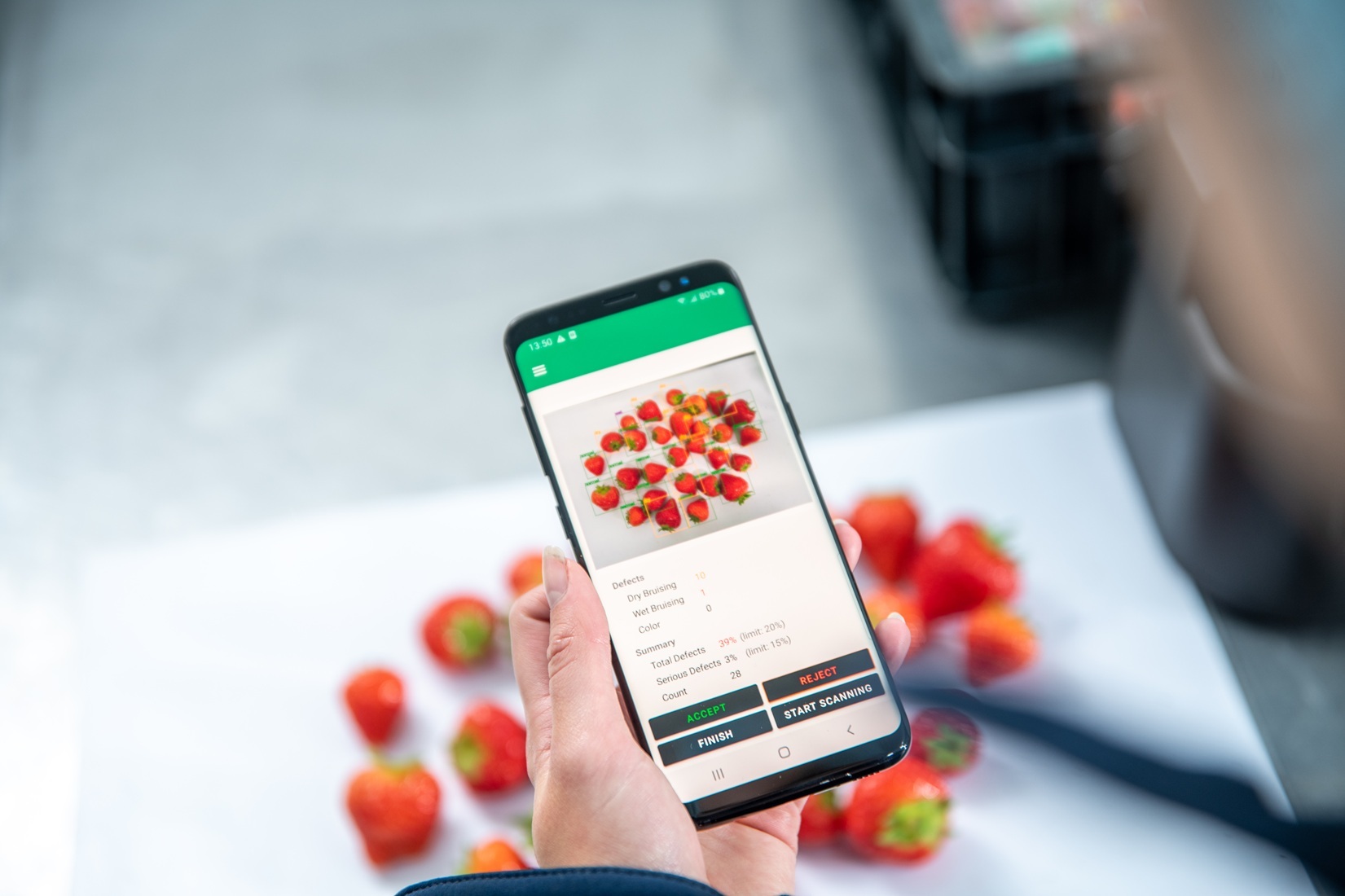

That’s why OneThird has developed a solution to predict shelf life in under a second by using a handheld device. By doing this, you can objectively compare various batches of fresh produce and base decisions on how long batch is expected to last.

Once you have a reliable method for ensuring a FEFO operation, you will see additional benefits.

What Will Improve When You Know Shelf Life?

There are numerous benefits for shelf life prediction, and they depend on the application.

Grower-shippers will see benefits at the quality dock because they will know which batch to send where.

For example, if you have one batch with six days of shelf life and one with ten, you will send the batch with six days to a closer location.

Shelf life prediction gives your customers the freshest produce and minimizes food loss.

Adding Shelf Life Prediction to Your Business

There are a few ways to predict the shelf life of fresh produce.

What’s important is making sure your business processes can make improvements from the shelf life data.

Be sure to read our free Ultimate Guide to Fresh Produce Shelf Life Prediction to learn more.

OneThird helps to make that happen by diving into your supply chain to see where the highest-return applications are.