21 Jun 2023

doorOneThird

Retailers inspect produce to make sure it meets their criteria. This leaves many decisions to be made. What should you do with fresh produce that is nearly bad? What about produce that is much fresher than the rest?

If you’re using shelf life prediction technology, you’ll have a lot of data to make decisions with. How do you know what to do with all of this freshness information?

This blog post will explain what you can do with above-spec and under-spec fresh produce to maximize the benefit to the business.

Why Produce Specifications are in Place

Produce specifications are an important way to achieve consistently high-quality products. Customers will continue to shop at your store if they know they will get fresh food. If these specifications weren’t followed, there would be a lot of guessing and poor decisions made.

While there are specifications between every part of the supply chain, there is often little to base decisions off of in-store.

For example, if strawberries have been on the shelf for three days how do you know if they are still good to sell or not?

Where “Best By” and “Sell By” Dates Fail

It’s known that one of the biggest reasons for food waste is consumers not knowing what exactly “best by” and “sell by” dates mean. ReFED determined that standardizing date labels can divert 398,000 tons of food waste per year and add $1.8 billion in economic value per year.

But what if these date codes are inaccurate in the first place? These are often conservative estimates that come as a result of “static testing,” which basically involves leaving them on a shelf to rot and coming up with an educated guess for what every batch will do.

However, by using our shelf life prediction technology we have seen that shelf life varies greatly between batches. There are a large number of factors influencing shelf life.

Date codes printed on packaging cannot magically change as a product ripens or rots.

If a produce manager sees a rotten apple that has a best by date of 4 days out, do you think they would still keep it on display? Hopefully not.

How to Determine Fresh Produce Shelf Life In-Store

Knowing real-time shelf life empowers produce managers to make better decisions.

Sadly, there aren’t magic wands to do this. But current technology is pretty close to that.

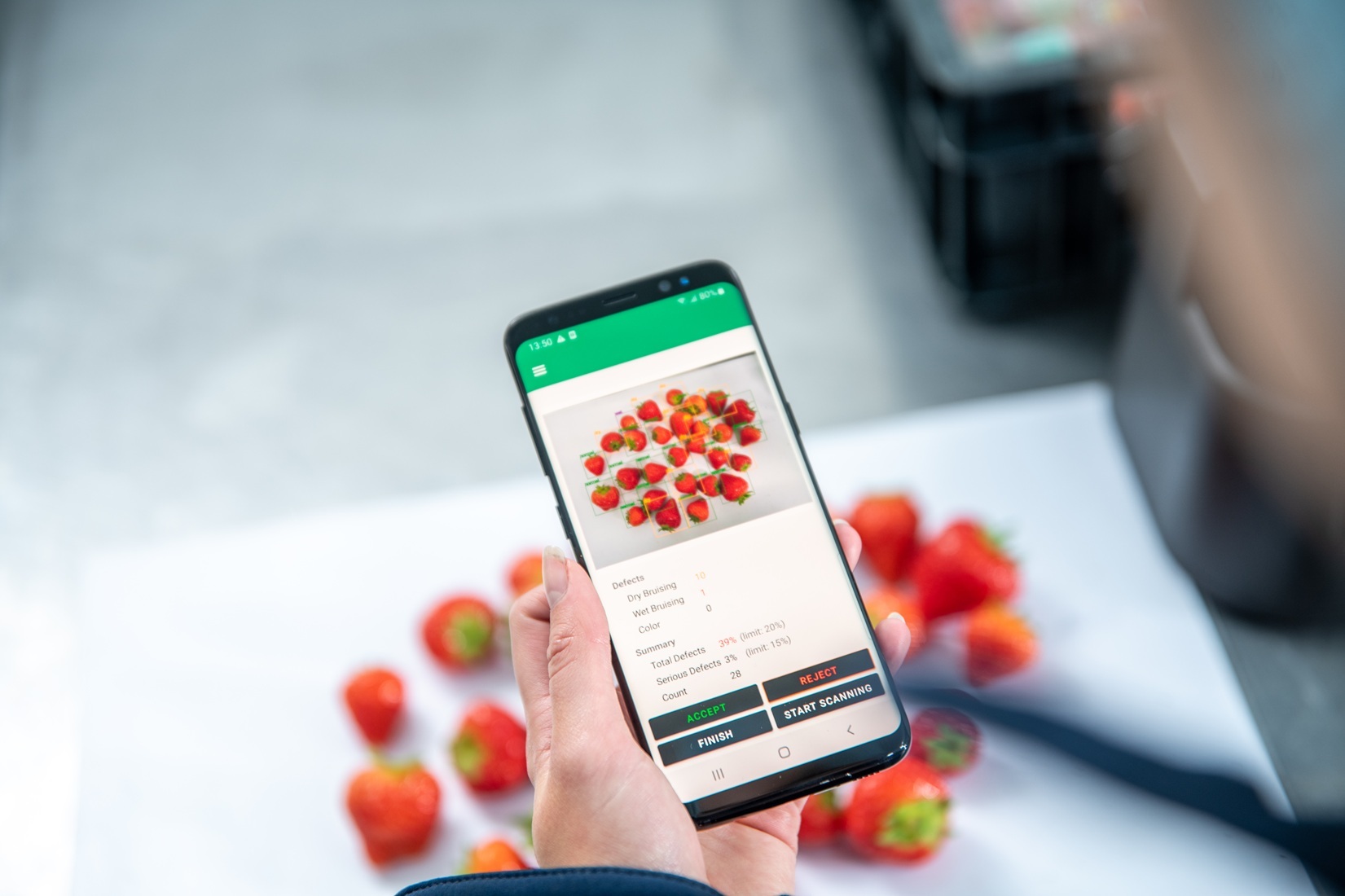

The most promising way to do this is by using handheld spectrometers. These devices are able to assess the current state of fresh produce using light and give a number of days it is expected to last.

Let’s say you have a carton of blueberries that have a best before date of tomorrow, but you find out the real shelf life is actually five days out.

It hurts every party to throw away healthy, uneaten fresh produce. It’s also expensive. ReFED has estimated the cost of food waste to retailers to be about $5,000 per ton.

With the ability to measure shelf life, you will then be left with three categories of fresh produce

Three Different Classifications of Fresh Produce

1. Reject (“Under Spec”)

Fresh produce which has a short shelf life or is a different size/shape/color than the standard is considered under-spec. Far too often, this is the food that gets wasted.

2. Acceptable

This is the lifecycle for the majority of your fresh produce. It’s still good enough to be sold, but not exceptionally fresh.

3. Exceptional (“Above Spec”)

Produce that exceeds the acceptable quality limits and is most likely to be bought by customers.

What to Do with Under-Spec Produce

Let’s say you scan a carton of blueberries that are supposed to be good for 4 more days, but they are expected to go bad in 2 days. If kept at the same price, it’s unlikely these blueberries will be sold other cartons- especially if they are not visually as appealing.

Here are a few things you can do to help sell or recover under-spec produce:

- Reposition the products so they are in front or on top

- Decrease the price

- Donate items to a food bank before they spoil

- Send for aerobic digestion

Many retailers fear their brand reputations will be hurt by selling “imperfect produce”. However, Imperfect Foods and Hungry Harvest have been successful by only selling imperfect produce.

Follow the Food Recovery Hierarchy

In deciding what to do with under-spec produce, it’s important to focus first on methods with a higher socioeconomic impact.

The EPA has put the Food Recovery Hierarchy in place to help determine what to do with the food you are getting rid of.

1. Repositioning

This is a common approach that is not the ideal choice. By repositioning, you are putting less attractive produce in front. This means the customer will sort through your items, potentially bruising them in the process. With a consistent price, this is the logical thing to do for customers, but dynamic pricing is a way to prevent this.

2. Decreasing price and dynamically pricing

Dynamic pricing involves changing the price of items based on the quality or expected quality. A simple version of this is already done in many stores. If you notice the sell-by date is in less than two days, you may put it in the clearance section for a lower price. Because the price is lower, more people are likely to buy it.

But what if the sell-by date isn’t accurate?

You may be putting produce with six days of freshness for half price and produce expiring tomorrow for full price.

The solution to this is using real-time shelf life prediction to objectively price fruits and vegetables. If you know how long every item will last, you can assign a price to that item that is most likely to maximize revenue and minimize waste.

3. Donating to a food bank or local livestock

There are fruits and vegetables that may not meet paying customer demands, but would somebody in need still appreciate it?

A large concern for retailers is the food they donate will cause someone to get sick, and they may get sued. However, there are a number of protections in place in the USA to prevent this worry. If you still think it is not fresh enough to be donated to humans, there may be animals that would love to eat it. Check with your local livestock farmers to see if they would accept it!

4. Sending for aerobic digestion or composting

Composting and aerobic digestion are ways to recover energy from uneaten food. Both involve capturing the nutrients/energy released from degrading fruits and vegetables. In the case of composting, it can be added to soil to help new plants grow. Anaerobic digestion converts the gases released into energy. However, this is an expensive method when you think about all of the time and money spent growing and transporting that food.

The economic value of centralized anaerobic digestion is only $21/ton of food waste and centralized composting is only $4/ton, according to ReFED. For comparison, ReFED has determined that the economic value of improved inventory management is about $1,194/ton. That’s almost 300x more beneficial than centralized composting!

What to Do With Items Exceeding Produce Specifications

It’s rare that produce managers treat items exceeding produce specifications differently. With the current evaluation methods in place, there isn’t much they can do.

However, with shelf life prediction technology you can determine objectively that some items are just fresher than others. This may be something that customers will pay a premium for, depending on the fruit or vegetable.

If you know that the longest shelf-life is of value to your customers, then why not charge accordingly for this? This can help in a few ways.

- Reduced waste, as customers will be more likely to buy the items closer to expiration

- Increased revenue, as some customers will pay a slight extra amount for longer-lasting produce

- Higher perceived value, as customers notice that you guarantee fresher produce than other stores and can prove it

Dynamic pricing benefits retailers for both under-spec and above-spec produce.

Summary

Relying on manufacturer-provided expiration dates leads to subjective decisions about selling fresh produce. This leads to increased waste and lost revenue.

You should focus on the top of the Food Recovery Hierarchy when making decisions on food. Produce specifications help, but they require subjective evaluation. Using shelf life prediction will help make informed, objective decisions about fresh produce.